History of Fused Glass

Along the shores of the Nile, Egyptian artisans first discovered a way to produce coloured glass objects through a mixture of silica, fluxes, and a variety of oxides melted at over 2500 degrees Celsius.

The Romans were much more prolific glassworkers, developing early fusing techniques.

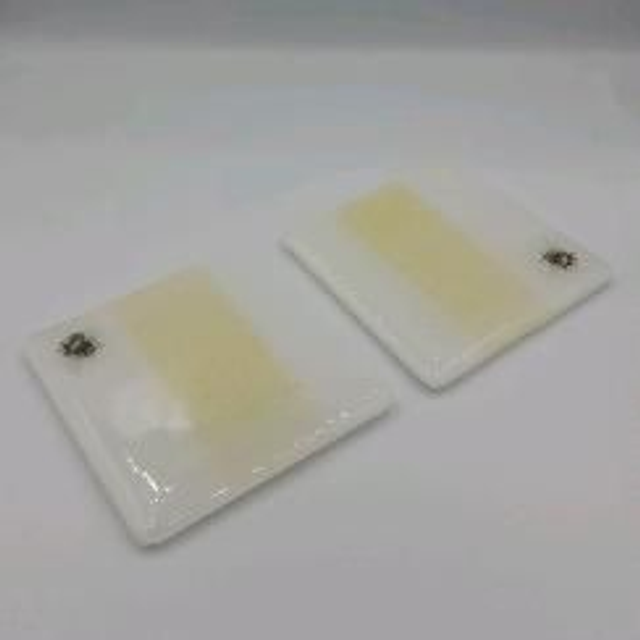

You can fuse glass without a kiln using a torch, and other specialized equipment, such as a microwave kiln. It's fun and rewarding hobby, and how I first started my journey, but it's important to take safety precautions and ensure that you have the necessary equipment and setup to work safely.

A microwave kiln is a container made of a white insulating fibre and lined on the inside of the chamber with a black compound that absorbs the microwave radiation and heats up to 898.889 degrees celsius.

If you have a programmable controller on your kiln you can begin fusing glass right now! The main difference between a glass kiln and a ceramic kiln, is that glass kilns generally heat a single layer from the top and ceramic kilns heat multiple layers from the side.

There are 4 main stages that occur when glass fuses together.

● 1200°F (650°C) Drape – glass softens enough to bend over a mold.

● 1250°F (675°C) Slump – glass softens enough to bend into a mold.

●1300°F (705°C) Fire Polish – glass melts enough to produce a surface polish.

●1350°F (732°C) Tack Fuse – pieces of glass will permanently fuse together.

GLASS SUPPLIERS

https://www.warn-glass.co.uk

https://linktr.ee/tabithasglassemporium